I have always felt fulfilled by making things using my hands and intricate processes, during my early teens I would often attend pottery workshops with my granddad, a leather worker. I felt fulfilled by learning the skills to create something physical that could sit in the home. I also have an interest in guitar pedals and would like to learn how to build them in the future in order to shape my guitar sound achieving unique tones. When starting this new project I knew I wanted to learn some physical skills that were transferable to other projects which is why I settled on soldering a circuit board for my two player Stylophone rather than using a Bela Board and coding to get the results I wanted.

I used the equipment in the Creative Tech Lab in LCC to solder and ordered the PCB online. The soldering station has a temperature display which stops at 300 degrees, a timer, a soldering iron, a fume extractor and a soldering iron tip cleaner. The display shows the user the temperature so they know when the iron is hot enough to begin soldering. The timer buttons can be pressed to turn the iron on, you press the button appropriate for however long you want to use the soldering iron for and once the time is up it turns the iron off as a safety measure. When soldering fumes are created which are toxic for humans, this is why the fume extractor is used. The tip cleaner is similar to a metal scourer and allows the user to wipe excess solder off the tip of the iron which lets the user be precise.

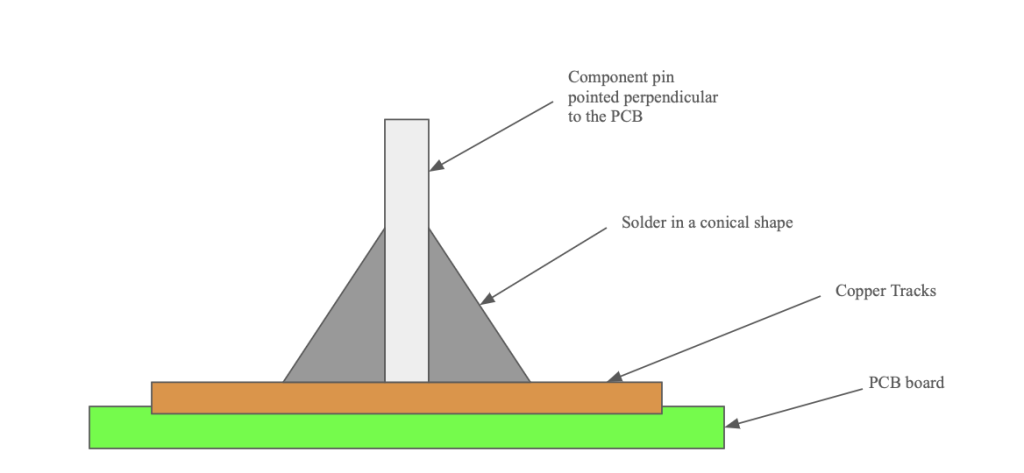

I had previously soldered once in secondary school, I soldered together a flashing LED circuit which I think involved resistors, an integrated circuit, LEDs however that is based on old memories. When relearning to solder I spent some time being inducted by Joanne Leung the physical computing specialist technician. She instructed me to ensure the soldering iron was clean and then put a very small amount of solder onto the iron, hold the iron against the pin of the component to allow it to heat up and then bring the solder to the pin and iron. The ideal shape of solder I needed to create to achieve the best joints possible is displayed in a diagram I have made based on ones I found in my own research displayed below.

I aim to continue soldering circuits based on existing schematics in order to understand circuits more, the more I build the more understanding I will gain and the more my physical computing skills will develop. Once I understand the design behind circuitry enough I will begin to design my own circuits allowing me to create tech more tailored to my needs.